Securing cargo within shipping containers is vital for safe and efficient transportation. By utilizing the inherent strength of the container’s structure, you can tightly pack cargo to minimize movement during transit. This is where lashing fittings come into play.

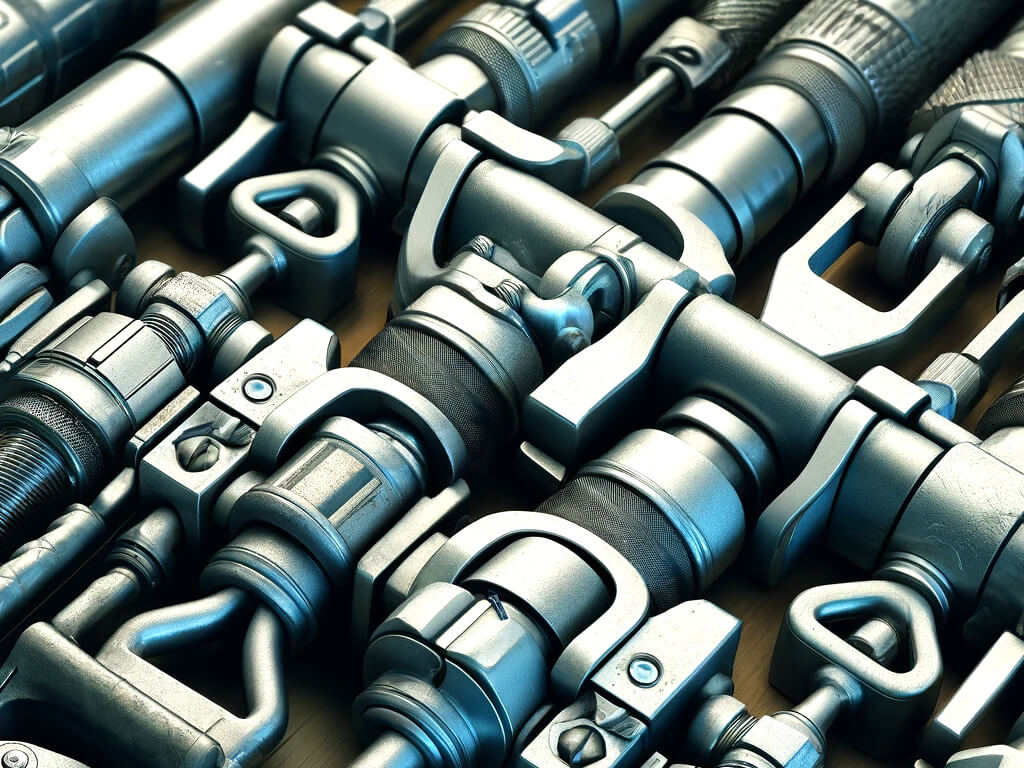

Lashing fittings, also known as container lashing rings, are strategically positioned anchor points within the container. Welded to the inner walls and floor, these fittings provide sturdy attachment points for securing straps, chains, or other restraints. By using these fittings, you can firmly anchor cargo, reducing the risk of shifting or damage en route.

What is the purpose of Container Lashings?

Inner lashing rings play a crucial role in ensuring cargo stability. Welded securely to the container’s base, these rings create robust anchor points for attaching hooks or restraints. This system offers a reliable means of securing various types of cargo, thereby enhancing safety and integrity throughout the shipping process.

Container lashings serve a crucial role in transportation, meticulously designed to safeguard cargo within shipping containers. Think of them as vigilant protectors of your goods, diligently ensuring everything remains securely in position. Their primary function is to prevent your cargo from shifting or jostling during transit, ensuring its stability and preservation. By employing effective anchoring and securing methods, these fittings emerge as the unsung heroes, guaranteeing the safe arrival of your shipments and shielding them from potential harm caused by unforeseen movements or instability while in transit.

The common types of container lashing fittings include lashing rings, as well as lashing bars or rods.

Where can you see Lashings in the Shipping Container?

You can find lashings within shipping containers, typically positioned on the interior side of standard dry van containers. They are welded onto various parts such as the top and bottom side rails, as well as the interior recessed front and rear corner posts.

In specific containers, you may notice lashing rings welded onto the front header at the recessed corrugations of the front panel. Additionally, some containers may feature lashing bars welded from the front header to the header extension plate, and also welded to the front sill at the recessed corrugations of the front panel.

Moreover, certain containers may have a lashing bar welded from the corner casting to the side top rail at all four corners. In some instances, lashing rings are also welded to the corner casting with the assistance of gusset plates at all four corners.

Feel free to reach out to us at +91 9998110007 without any hesitation.